Statox 560 gas detector – self-test with real gas

Detection of Phosgene COCl2, Chlorine Cl2, Hydrogen Cyanide HCN, Carbon Monoxide CO, Hydrochloric Acid HCl, Ammonia NH3 or Hydrogen Sulfide H2S (others upon request) at the highest safety level!

Functional safety with SIL2 gives you a good idea of the extremely low probability of failure on demand. In addition, a self-test with real gas makes sure that no fault – no matter how unlikely – will go unnoticed.

The self-test also helps you to determine the next maintenance event. It provides reliable information about the remaining lifetime of the sensor. This saves a lot of time avoiding routine inspections.

Quick navigation:

Features | Technical data | Self test | Downloads

Features of the Statox 560 gas detector

The Statox 560 is a state-of-the-art product in any respect:

- The new generation of sensors provides high sensitivity, very fast response, low cross-sensitivity and plug-and-play technology.

- The built – in gas generator produces the gas to be measured during the self-test. This way you can always be sure that the sensor is in good condition.

- The Statox 560 is a 4 – 20 mA transmitter.

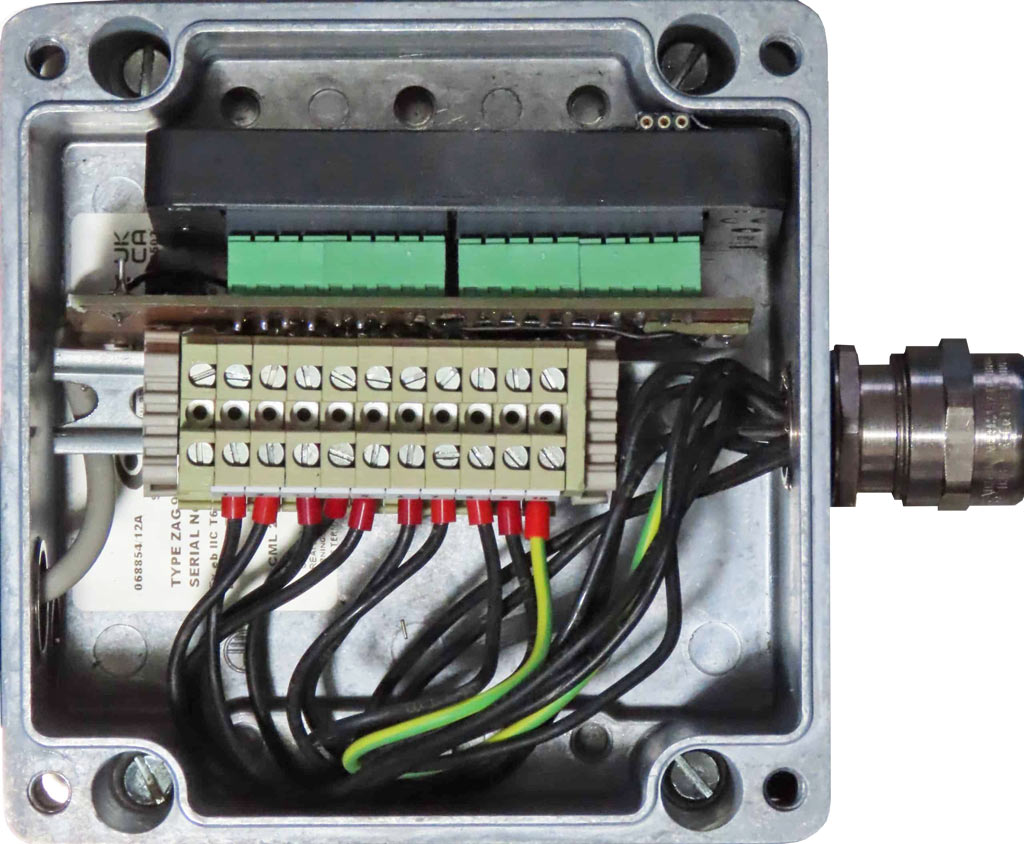

- The entire electronics are housed in an Ex d enclosure with a window. The self-test takes place automatically once a day at a programmable time. However, it can also be triggered manually on site using a magnetic pen. The self-test can also be started from the control room. This is done with a separate button or with the Statox 503 Control Module.

- A magnetic pen is used to set parameters and read out information such as calibration data, exposure, maintanance request etc. As the housing must not be opened, no hot work permit is required.

- The sensor module includes the sensor, the generator cell and a micropump. It is designed in protection class Ex i. There is no hot work permit required to work on this module. Another option would be to replace the entire module. This way you can do all work on it in the comfortable environment of your workshop.

This product provides a maximum on safety and user-friendliness.

Technical data gas detector Statox 560

| Product Name: | Statox 560 (Type 5377) |

| Power Supply: | 24 (16-30) VDC |

| Power Consumption: | max. 2.7 W (8.7 W for COCl2) at an input voltage ≤ 26 VDC |

| Operating Temperature: | -30 to +60 °C |

| Pressure Range: | 700 to 1300 hPa |

| Humidity Range: | 0% to 99% r. H., non-condensing |

| Application Range: | II 2G |

| Explosion Protection: | Ex d ib IIC T4 Gb (Um = 30 VDC for all connections!) |

| EU Type Approval Certificate: | BVS 16 ATEX E 065 X |

| Ingress Protection: | IP66 (Gas entry opening IP54) |

| Display: | 2 x 16 characters, illuminated |

| Housing: | Aluminium die-cast with epoxy coating / stainless steel |

| Connections: | 10-wire cable tail (1 m) or 7-pole eXLink plug connection |

| Open-Drain Outputs: | 2 x Alarm, 1 x System Error, 1 x Maintenance Required Connection ratings: each max. 30 VDC / 2.5 A |

| SF-Open-Drain Output: | Active in normal operation (conducting) |

| Analog Output: | 0 mA in case of error; 2 or 4 mA in service mode, adjustable 4 – 20 mA in measurement operation 22 mA for overrange max. load: 450 Ohm |

| EMC: | EN 61000-6-4:2007 + A1:2011 / EN 50270:2015 (Type 2) |

| Functional Safety: | SIL 2 capable according to IEC 61508:2010 |

| Automatic Self-Test: | every 24 hours, selectable time |

| Weight: | approx. 4800 g |

| Dimensions (WxHxD): | 121 x 294 x 138 mm |

Self-test

| Gas | Formula | Test Gas |

| Chlorine | Cl2 | Cl2 |

| Carbon Monoxide | CO | H2 |

| Phosgene | COCl2 | COCl2 |

| Hydrogen Sulfide | H2S | H2S |

| Hydrogen Cyanide | HCN | HCN |

| Ammonia | NH3 | H2S |

| Hydrogen Chloride | HCl | H2S |

Downloads

Suitable control module:

Statox 503

Dr. Josef von Stackelberg

Managing Director COMPUR MONITORS GmbH & Co. KG

Contact us without obligation

Do you have any questions about our products or would you like a non-binding consultation? We look forward to hearing from you.